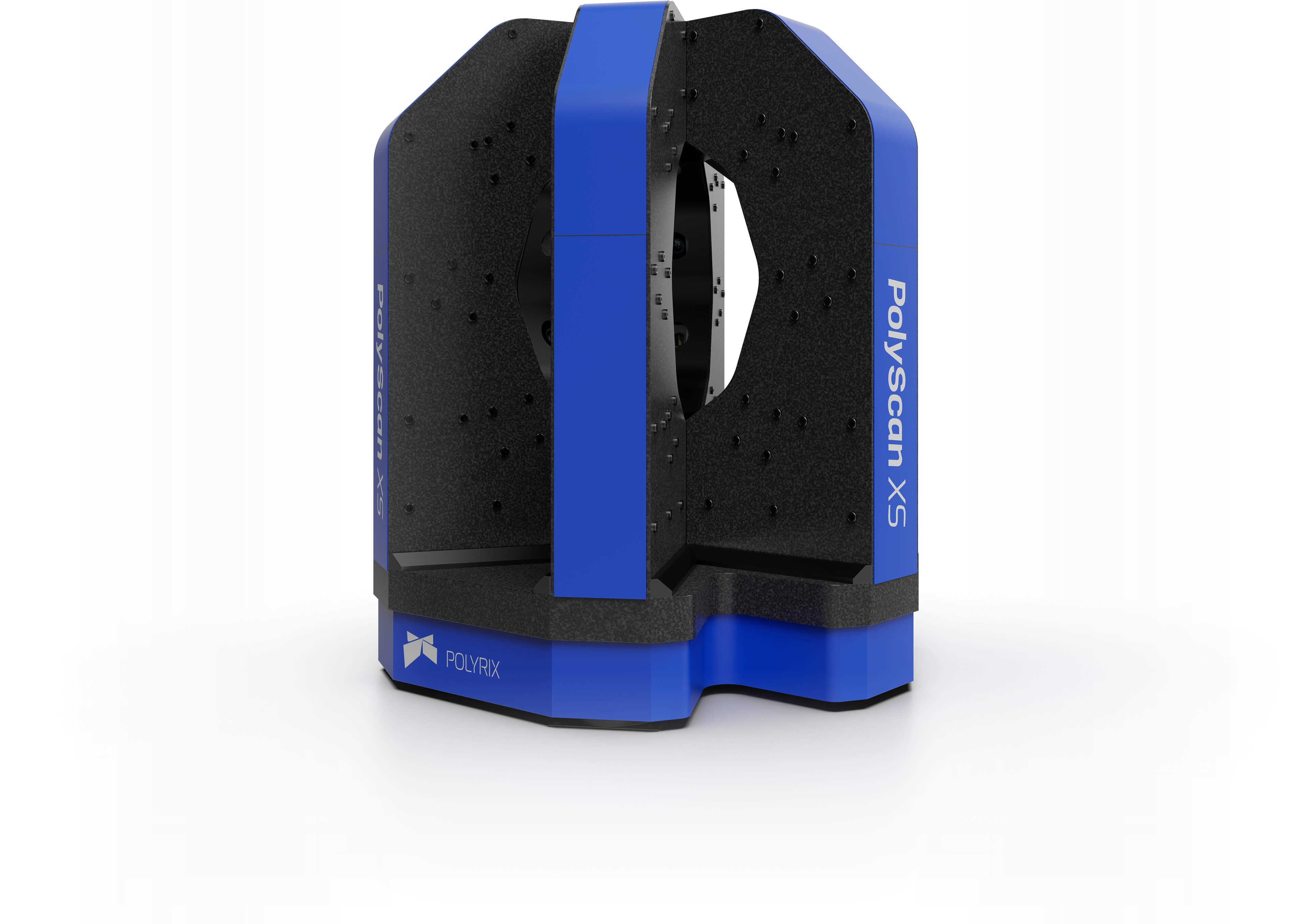

Maximum precision, maximum resolution

3D measurement system for parts up to 250 mm

Compare with other Polyscan models

| PILLARS | SCAN VOLUME |

SCAN TIME |

SCAN TIME WITH |

VOLUMETRIC ACCURACY* |

VOLUMETRIC ACCURACY WITH |

MAX PART SIZE |

|---|---|---|---|---|---|---|

| 6 | 15 cm (L) x 15 cm (W) x 25 cm (H) | 6-8 minutes | 22 seconds | +/- 0.010 mm | - | 0.25 m |

Switch to landscape to see the whole table.

They Trust the Power of the PolyScan XS

Polyrix Customer Sample

An instrument

of perfection

Laboratory table principle: a structure made of granite for optimal metrology dynamics supported by vibration damping mounts.

The PolyScan XS offers Polyrix’s highest level of accuracy and resolution as a high-resolution 3D scanner for small objects, so it is well suited for small parts.

PolyScan XS FAQs (Frequently Asked Questions)

The PolyScan XS is a compact 3D scanning system designed for small to medium-sized parts. It delivers fast, full-surface capture using a fixed, no-moving-parts design. Ideal for labs, R&D, and inspection cells, it offers high accuracy in a small footprint.

Is your company interested to learn more about Surround 3D Scanning?

Polyrix would be glad to perform a free scanning demonstration with one of your part.

** Based on VDI/VDE 2634 part 2 third-party evaluation ISO 17025 accredited laboratory - NIST Traceability