From Lab Bottlenecks to 100% Inline Inspection

By Polyrix

A super quick read.

Aug 20, 2025

Challenge

- Takt time: 49 seconds

- Only 10% of parts scanned due to robotic system limitations

- Significant rework and recall risk

- Offline lab inspections added 2+ hours per rejected part

Polyrix Solution

- Full part scan in 26 seconds (under takt time)

- Real-time “go/no-go” signals to the PLC

- Automatic deviation alerts—even within threshold

- Inline integration, no dedicated operator needed

Outcome

- 100% inline inspection of 1,600 transmissions/day

- 98% reduction in reworks

- Over $1M/year saved per line in labor, reworks, and space

Get a PDF Case Study in your Inbox

Relevant posts

Subscribe to Our Blog

Related Posts

Generative 3D from Images vs. Industrial 3D Scanning

Feb 17, 2026

2 min read

Recent advances in AI generative models have enabled impressive methods for re.

Exploring the Different Types of Automated Coordinate Measuring Machines (CMMs): Tactile Probe, Laser Interferometry, Laser Scanners, Structured Light, and X-Ray for Precision Manufacturing

Nov 6, 2025

5 min read

Introduction to Industrial Metrology and Quality Assurance In modern manufactu.

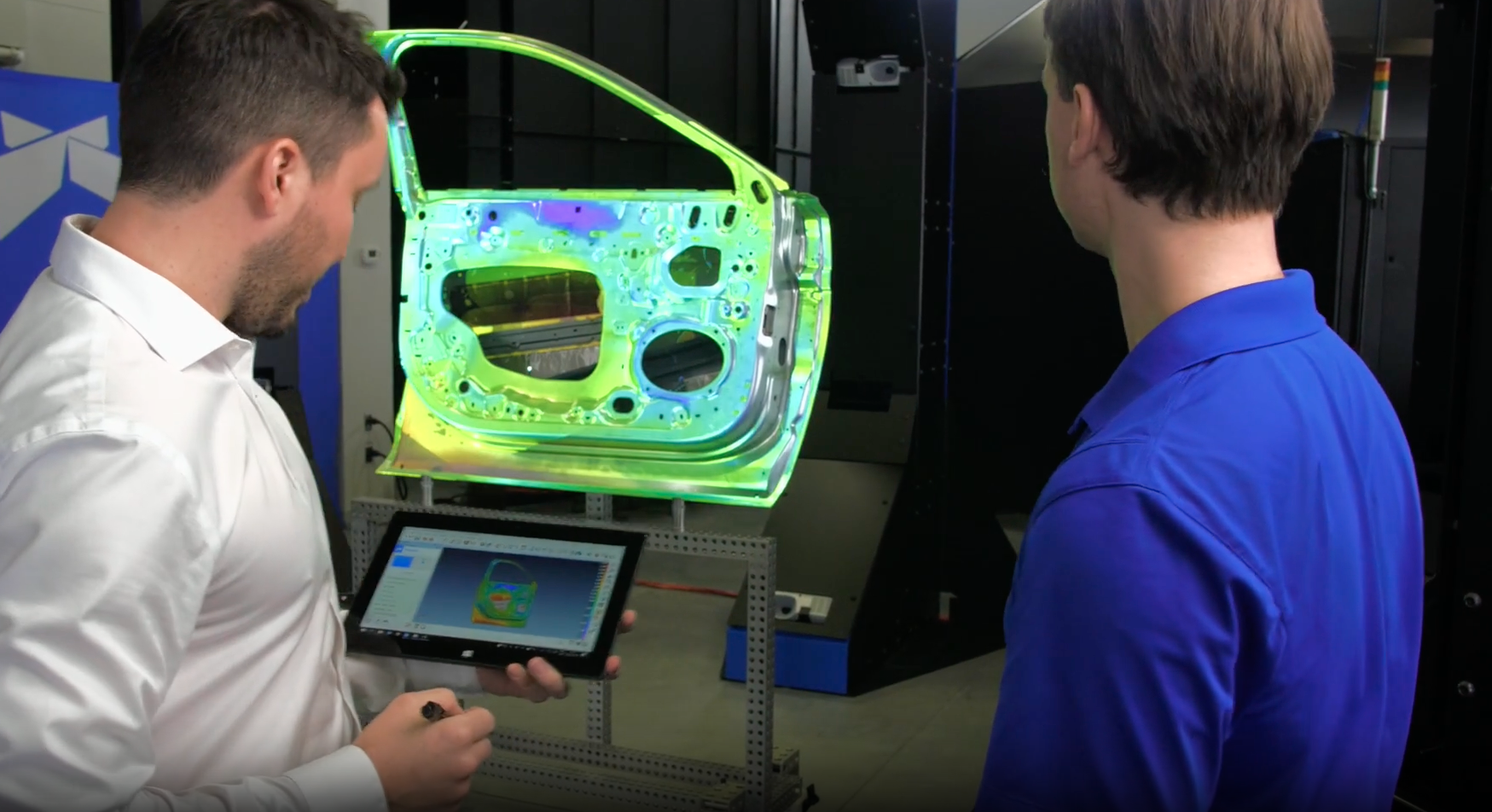

The Automotive Quality Future: Industry 4.0 & Motionless 3D Inspection

Dec 15, 2025

3 min read

Automotive manufacturing is entering a new era, one whereprecision, speed, and.