The Automotive Quality Future: Industry 4.0 & Motionless 3D Inspection

Automotive manufacturing is entering a new era, one where precision, speed, and adaptability define competitive advantage. Yet many production environments still rely on outdated processes designed for slower, less complex operations. At Polyrix, we believe the key to unlocking the next leap in efficiency isn’t just more automation or higher-quality machines, it’s enabling every phase of manufacturing to communicate seamlessly.

In this blog, we explore how connected manufacturing transforms the automotive ecosystem and how technologies like motionless 3D scanning help manufacturers produce at velocity, reduce costs such as material waste and speed decision making while improving quality.

In order to achieve Industry 4.0, there are many factors that come into play. The contribution of Polyrix is key to the whole process, because our goal is to provide the right, accurate information, at the right moment in the process. Once the information is available, automation can be achieved.

Rethinking Automotive Production

For decades, automotive manufacturing has been organized as a sequence of highly specialized steps: design hands off to production, production hands off to inspection. If problems appear late in the process, teams must retrace steps, often at great cost.

The challenge isn’t the expertise of these teams; it’s the fragmentation between them. When data stays isolated, decision-making slows, and issues surface only after they become expensive to fix.

Leading automotive manufacturers are shifting from segmented workflows to connected ecosystems, where quality data flows instantly across the three phases of manufacturing: design, production, and inspection. This shift allows organizations to catch issues earlier, react faster, and continuously improve without halting production.

1. Design: Smarter, Faster, More Predictive

Modern engineering teams no longer rely solely on physical prototypes to validate concepts. Digital simulation, AI-driven analysis, and fast metrology feedback allow designers to:

- Identify feasibility issues before tooling is created.

- Explore more possibilities in less time.

- Validate tolerances against real production conditions.

When inspection data flows directly back into design, engineering becomes proactive, not reactive. Problems are solved long before they reach the factory floor.

2. Production: Data-Driven Agility

Once designs are approved, the production line becomes the engine that transforms concepts into reality. But without actionable data, even the best processes risk bottlenecks, scrap, and rework.

With connected systems, production teams can:

- Monitor deviations as they emerge.

- Reduce the number of physical prototypes.

- Adjust tooling and programs in real time.

- Maintain stability across high-mix and high-volume operations.

This creates a more agile environment, where flexibility increases and costs drop without compromising throughput.

3. Inspection: The Engine of Continuous Improvement

Inspection has traditionally been treated as the final approval stage, an end-of-line check against standards. Cutting-edge manufacturers are elevating inspection to a strategic asset.

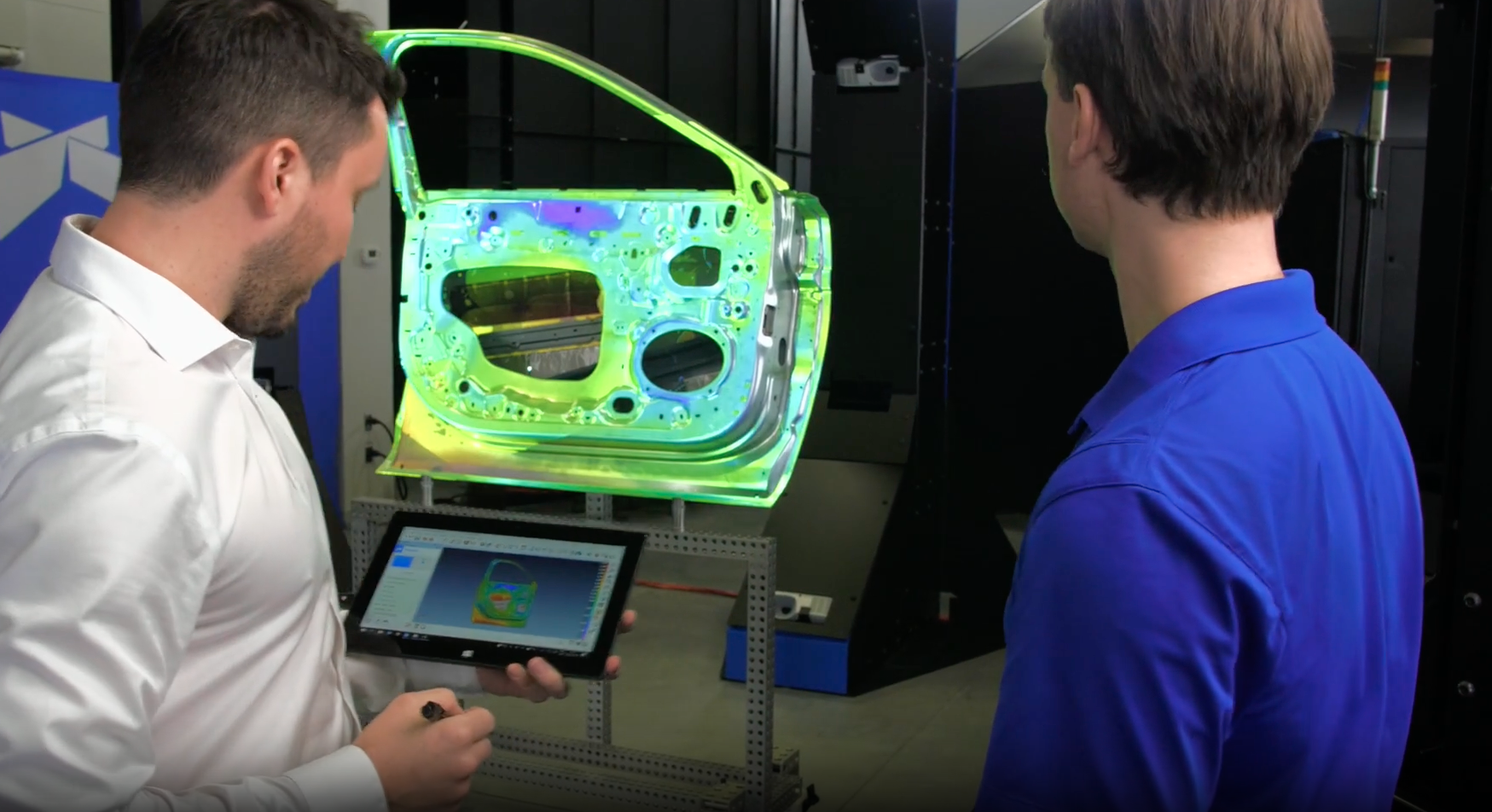

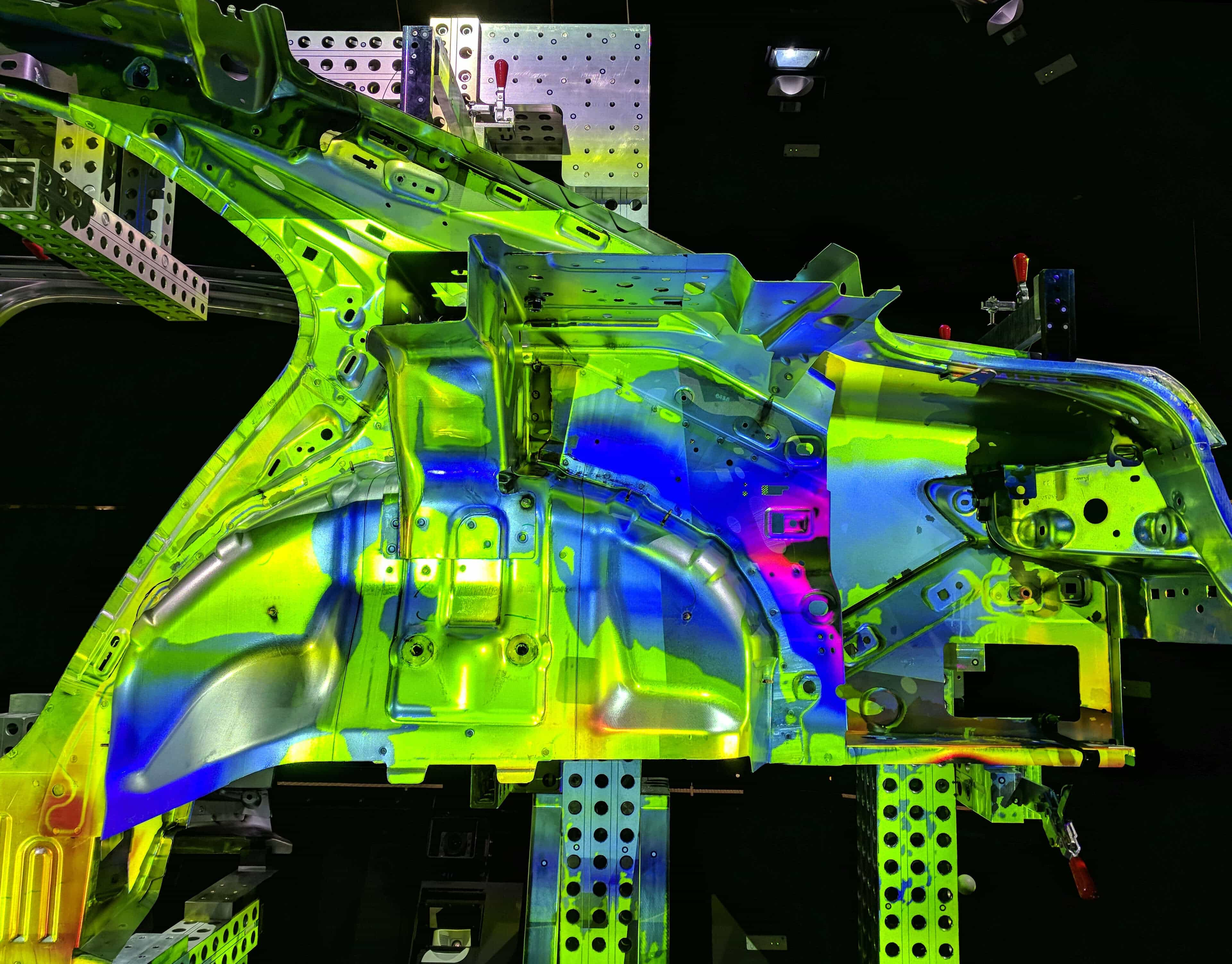

With Polyrix’s motionless 3D scanning, inspection becomes:

- Faster, producing full-coverage results in seconds.

- Repeatable, with no operator-dependent variation.

- Integrated, feeding data instantly back into both engineering and production.

Rather than acting as a gate that slows output, inspection becomes the force multiplier that accelerates innovation and strengthens product quality.

The Impact: Less Waste, More Precision, Better Vehicles

When the three phases of manufacturing (design, production and inspection) connect through real-time data, it unlocks benefits that were previously impossible at scale:

- Early detection of defects eliminates downstream rework.

- Traceable, high-density measurement data simplifies compliance and root-cause analysis. A digital twin ensures the quality of each part is traceable throughout its journey.

- Shorter development cycles reduce time-to-market for new vehicle models.

- Greater process stability improves safety, reliability, and customer satisfaction.

- Lower operating costs, driven by fewer prototypes, less scrap, and rapid troubleshooting.

This isn’t just operational optimization, it’s a structural advantage. Manufacturers that activate connected ecosystems outperform those relying on traditional checks and balances.

Why Automotive Leaders Choose Polyrix

Polyrix’s motionless 3D scanning is purpose-built for environments where speed, precision, and reliability matter most. Our systems eliminate extraneous robot paths, reduce maintenance, and capture full-part coverage instantly, making automated inspection viable even for large, complex components.

With solutions trusted across automotive, aerospace, and advanced manufacturing, we help organizations:

- Automate high-accuracy inspection

- Integrate metrology data directly into quality and design workflows.

- Improve throughput while maintaining tight tolerances.

- Establish a smart, connected manufacturing framework.

Conclusion: The Future Belongs to Connected Manufacturing

The automotive industry is evolving, and manufacturers embracing connected workflows are setting the pace. By enabling real-time communication between design, production, and inspection, organizations reduce waste, improve agility, and bring better vehicles to market faster.

While it seems complicated, it’s really about bringing simplicity back to the manufacturing industry and production floor. The first step is the access to the right information at the right step because once you have the right process, automation is truly made simple.

Polyrix supports this transformation with cutting-edge metrology technology designed for the future of automotive manufacturing. If your team is ready to streamline processes, eliminate bottlenecks, and accelerate quality, contact us today.

Subscribe to Our Blog

Related Posts

Mastering 100% Inline 3D Inspection: Speed, Accuracy & Traceability

Transforming Manufacturing with Screenless Augmented Reality