Transforming Manufacturing with Screenless Augmented Reality

Manufacturers today face mounting pressure to deliver flawless products faster than ever. The ability to identify and correct issues immediately is no longer optional—it’s a competitive necessity. Automated visual inspection, using augmented reality (AR), is emerging as a powerful ally in meeting these demands. Polyrix’s Live.Inspection™ blends advanced 3D scanning with screenless AR visualization to enable instant, accurate, and actionable automated inspection directly on the production floor.

What is Live.Inspection™?

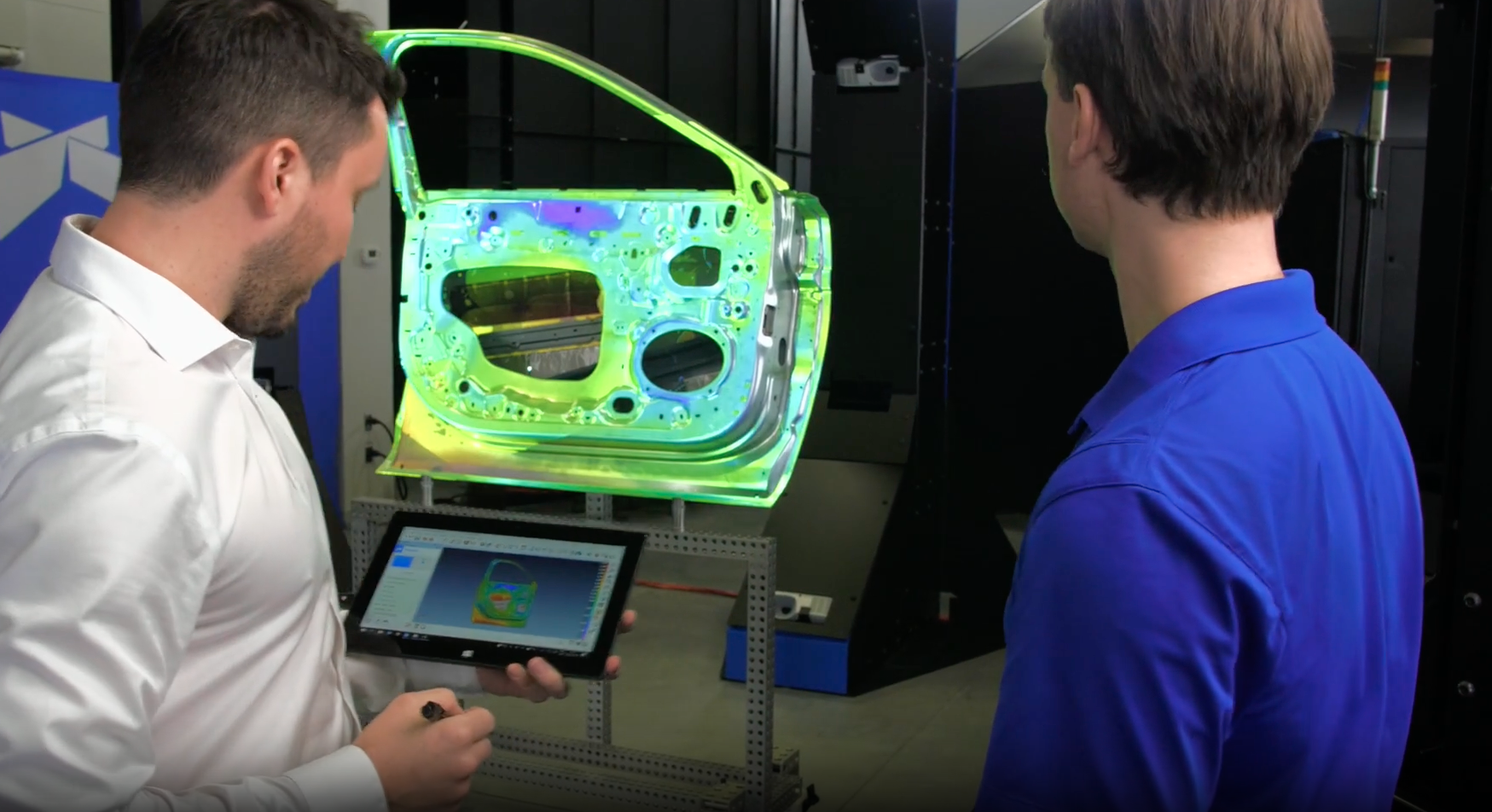

Live.Inspection™, a patented Polyrix technology, enables real-time inspection by comparing a manufactured part to its CAD model without removing it from the production line or sending it to a metrology lab. The system projects directly onto the object a color map of tolerance levels and other key information, without the need for additional glasses or screens. Typically, green indicates that a part passes the threshold, while red highlights areas requiring attention—along with other colors in between.

Its precise 3D scanning and intuitive color mapping instantly reveal dimensional deviations, helping teams catch and fix defects before they escalate. The result? Faster inspections, fewer bottlenecks, and consistently high product quality. Additionally, the projection-based visual inspection automation allows groups of people to collaborate in real time, even standing around the same part and pointing to precise issues, minimizing communication errors and orientation challenges. This shared, tangible reference makes discussions more efficient and effective and further supports automated inspection in manufacturing.

Its precise 3D scanning and intuitive color mapping instantly reveal dimensional deviations, helping teams catch and fix defects before they escalate. The result? Faster inspections, fewer bottlenecks, and consistently high product quality. Additionally, the projection-based visual inspection automation allows groups of people to collaborate in real time, even standing around the same part and pointing to precise issues, minimizing communication errors and orientation challenges. This shared, tangible reference makes discussions more efficient and effective and further supports automated inspection in manufacturing.

Deviation map applied on the scan data Deviation map applied on the scan data |

Deviation map displayed on the part Deviation map displayed on the part |

Close-up of the deviation map displayed on the part |

Automated Visual Inspection Systems Enable Instant Insight on the Shop Floor

Critical inspection data overlays directly on the physical part, allowing operators to:

- Visualize deviations in real time with easy-to-read pass/fail overlays.

- Reduce inspection time by eliminating manual measurements.

- Improve accuracy with clear visual cues that guide decision-making.

- Rework immediately with color maps showing exactly where adjustments are needed.

- Follow visual instructions for assembly and placement directly on the part.

This real-time feedback ensures every team member—from operators to engineers—sees the same accurate data, minimizing miscommunication and costly errors.

Perfecting Processes Before Production

Beyond augmented reality, Live.Inspection™ expands its potential by enabling teams to plan, simulate, and collaborate in a virtual environment. Using the Live.Inspection™ data makes it possible to:

- Validate setups before production to catch design or alignment issues early.

- Collaborate without additional wearables, avoiding the costs, safety concerns, and discomfort often associated with glasses and other wearables.

- Share important information: configure what is projected onto parts, including instructions, assembly guidelines, fluid flow dynamics, FEM (finite element method) data, or any other pertinent insights.

Why Manufacturers Choose Live.Inspection™

When looking to create or optimize automated inspection, manufacturers look for an edge while maintaining profits. Live.Inspection™ allows manufacturers and quality teams to perform by delivering:

- Speed: Accelerate the time it takes to interpret results and collaborate, thanks to clear projections that provide a single source of truth.

- Quality: Catch and address defects immediately, before they escalate.

- Cost savings: Reduce waste, rework, and downtime.

- Clear communication: Enable teams to work with a shared visual language.

Industry Applications

Live.Inspection™ brings value across multiple sectors of manufacturing, from automotive to aerospace. All manufacturers can benefit from automated quality control inspection. Some industry examples include, but are not limited to, the following:

- Automotive: Ensuring precise alignment of parts such as body panels or battery trays and validating assemblies during production.

- Aerospace: Inspecting turbine blade defects and supporting rework of large castings.

- Heavy Equipment: Performing in-place inspections of large welded or assembled components.

Seamless Integration

Live.Inspection™ integrates seamlessly with existing CAD and manufacturing systems. Flexible setups, customizable reporting, and intuitive controls mean minimal disruption during adoption. Live.Inspection™ comes with every PolyScan system—there is no extra software or hardware required. Just scan, inspect, and project.

In Summary

Augmented reality is reshaping manufacturing, and Polyrix’s Live.Inspection™ delivers this innovation in a practical, production-ready package—without relying on screens or costly glasses. By merging high-speed 3D scanning with intuitive visual feedback, Live.Inspection™ gives manufacturers the power to understand, communicate, and act instantly on valuable insights. The result is a smarter, more connected factory environment where engineering, quality, and production teams collaborate seamlessly around a shared, real-time view of each part.

This technology not only accelerates inspection but also supports continuous improvement across production lines. By integrating directly with CAD systems and existing workflows, Live.Inspection™ transforms data into action—helping teams move from reactive quality control to proactive process optimization. Manufacturers who adopt this approach see stronger product consistency, lower rework rates, and improved operational efficiency.

With real-time visualization and simulation, manufacturers can achieve higher quality, faster turnarounds, and lower costs, while building a foundation for the next generation of digital manufacturing.

Experience the future of manufacturing inspection.

Contact Polyrix today to see Live.Inspection™ in action.

Relevant posts

Subscribe to Our Blog

Related Posts

Mastering 100% Inline 3D Inspection: Speed, Accuracy & Traceability

Revolutionizing Adaptive Manufacturing for Collins Aerospace