Exploring the Different Types of Automated Coordinate Measuring Machines (CMMs): Tactile Probe, Laser Interferometry, Laser Scanners, Structured Light, and X-Ray for Precision Manufacturing

Introduction to Industrial Metrology and Quality Assurance

In modern manufacturing, industrial metrology—the science of precise measurement—is essential for quality control and production efficiency. From automotive to aerospace and medical devices, accurate metrology ensures components meet specifications, reduces scrap, and optimizes throughput. It's important to balance quality with requirements; over-specifying parts can be costly, while failing to check quality can lead to defects. Choosing the right automated metrology system directly impacts productivity, measurement accuracy, and cost savings.

The goal of any CMM is to measure precise points on a part to create accurate 3D geometries that support manufacturers with part identification, quality assurance, and traceability of finished products.

This guide compares top automated CMM technologies — Tactile Probe, Laser Radar, Laser Scanners, Structured Light (like Polyrix Surround.Scan™), and X-Ray/CT Metrology. We also review offline, at-line, and inline inspection methods, highlighting advantages, limitations, and best-use cases. Learn how these technologies can be integrated into automated production lines, including robotics, for modern manufacturing.

Tactile Probe CMM – High-Accuracy Contact Measurement

Tactile Probes, also known as Contact Probes, are a foundational industry standard for dimensional metrology, using physical contact.

Advantages of Tactile Probe CMM:

- High precision and repeatability

- Works on any type of surface finish (even mirror or transparent)

- Ideal for small-to-medium parts

- Stable, traceable calibration

Limitations of Tactile Probe CMM:

- Point-by-point probing slows cycle times, less suitable for inline inspection

- Requires controlled lab environments

- Limited access for complex geometries

- Requires contact with the part (risk of collision or damage)

- Repair costs for damaged probes can be high

Best for: Ultra-precise dimensional verification where accuracy is prioritized over speed.

Laser Interferometry and Laser

Scanning – Non-Contact 3D Measurement

Laser interferometry systems, or laser scanners, create dense 3D point clouds by sweeping a laser across the part surface. They offer fast, non-contact inspection of large components. Although one uses triangulation and the other a single laser (interferometry), their advantages, disadvantages, and use cases are similar.

Advantages of Laser Interferometry and Laser Scanning:

- High-speed scanning of large assemblies (slightly slower than structured light systems)

- Non-contact, avoiding collision issues

- Excellent for freeform surfaces

- Interferometry: Limited accuracy for large assemblies; very accurate at a single depth

Limitations of Laser Interferometry and Laser Scanning:

- Sensitive to vibration, lighting, and surface reflectivity

- Slightly less accurate than tactile probes for fine tolerances

- Line-of-sight limitations

- Surface finish can impact results

- Generally requires robotic positioning to maintain laser alignment

Best for: High-throughput inspections where speed and surface coverage are critical.

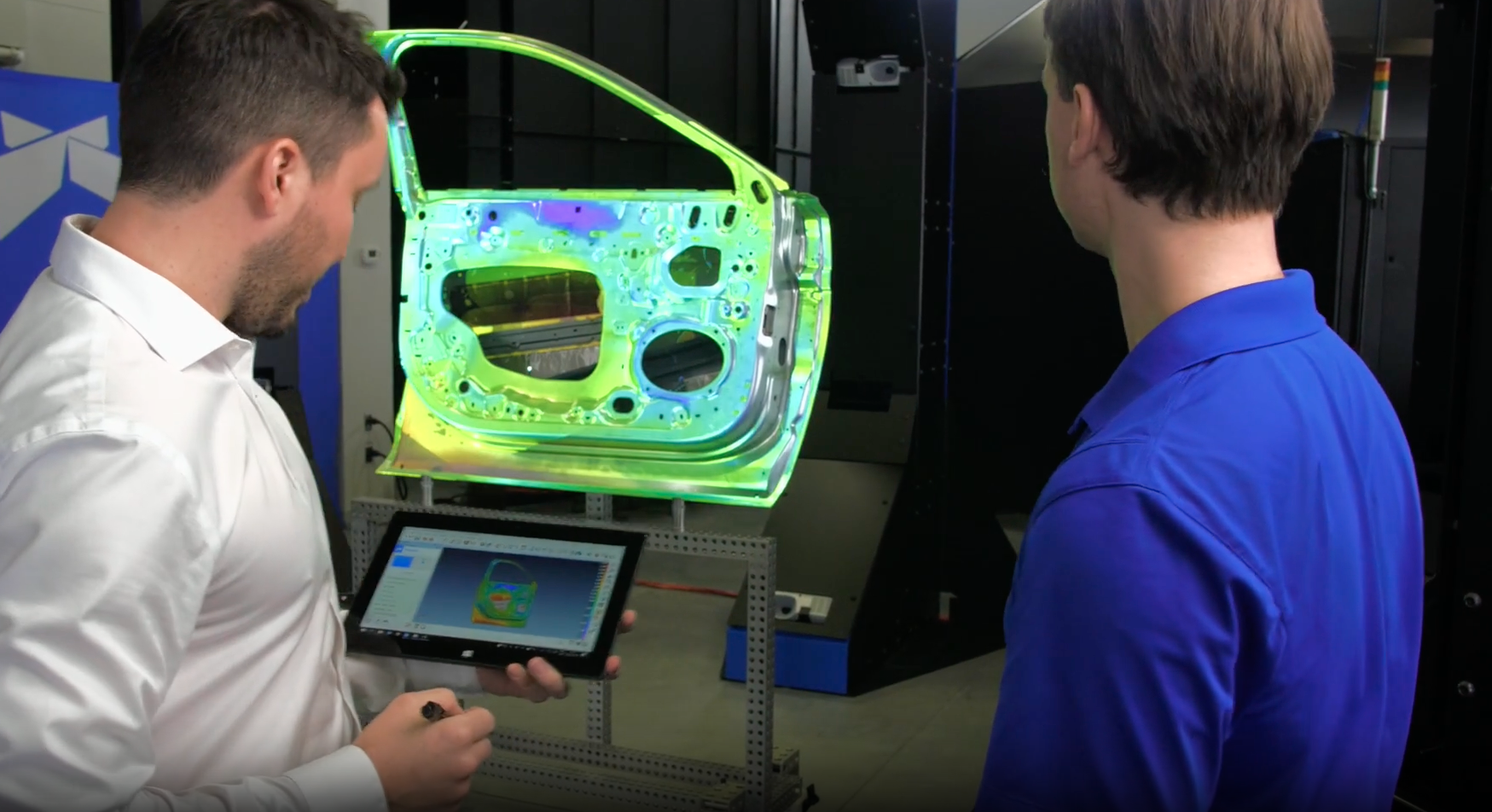

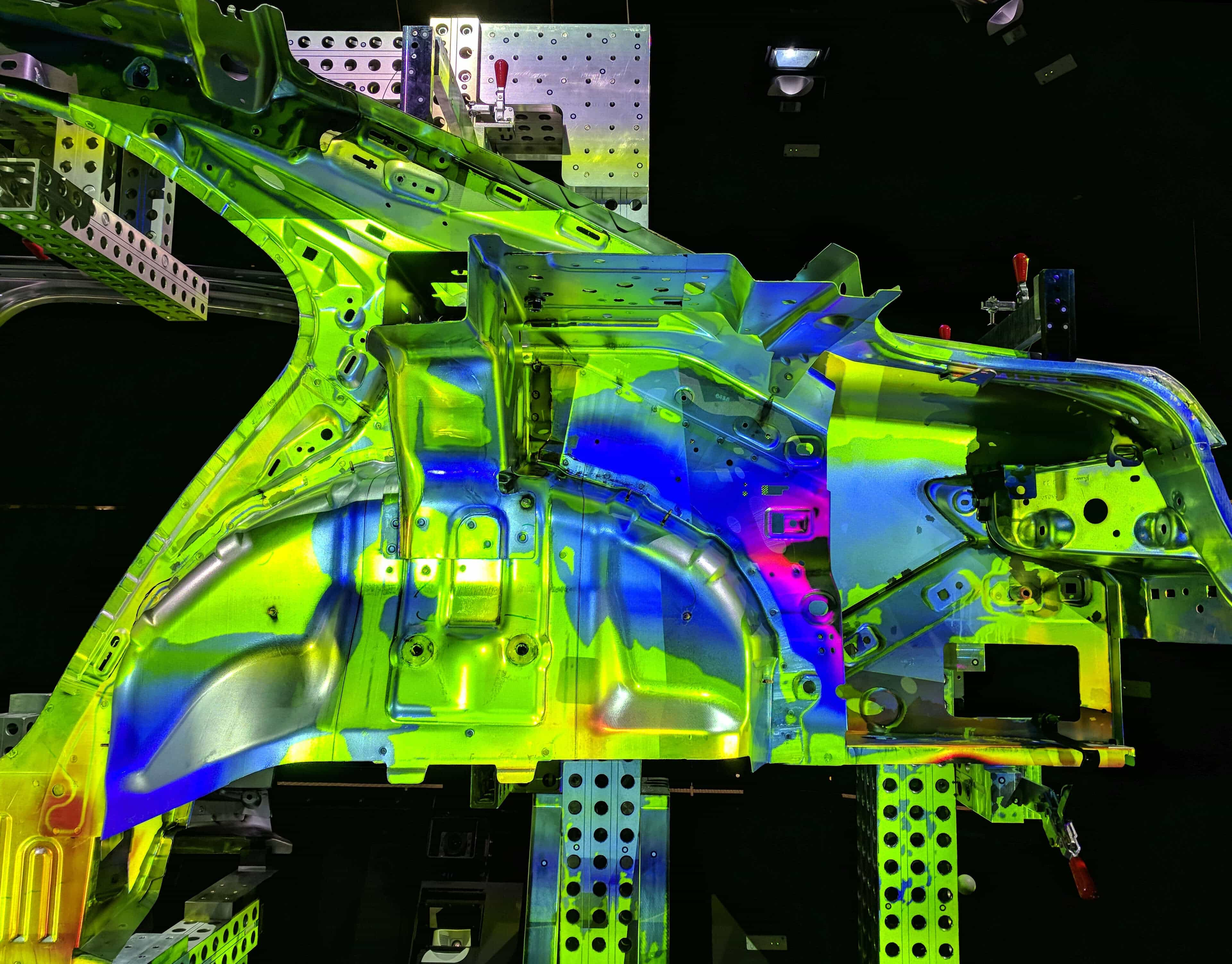

Structured Light CMM – Optical 3D Scanning with Polyrix Surround.Scan™

Structured Light uses a projected pattern to capture more data at once, converting images into a full 3D model using advanced algorithms. This non-contact optical metrology is ideal for inline, at-line, or offline inspection.

Two common configurations exist: a movable single system on a robotic arm or a fixed array. Polyrix’s Surround.Scan™ uses a fixed array of multiple scan units around the part, saving time and increasing data capture speed.

Advantages of Structured Light:

- Fast full-field data capture in seconds

- No part movement or contact required if surround configuration is used

- Adaptable: single movable system or multiple sensor array

- Scalable for small to large assemblies

- Flexible for production integration

Limitations of Structured Light:

- Lighting may affect accuracy

- Surface finish can impact results

- Line-of-sight limitations

- Hidden features may require additional scan units

- If not part of an array, a robot or turntable is likely required

Best for: Automated high-speed inspection with full coverage and flexibility.

Polyrix Surround.Scan™ combines multiple sensors and structured light for 360° capture without part rotation or targets, making it ideal for inline and at-line metrology.

X-Ray and Computed Tomography (CT) CMM – Internal and External Inspection

X-Ray/CT metrology allows non-destructive measurement of internal and external geometries.

Advantages of X-Ray and Computed Tomography (CT):

- Detects internal defects, cracks, and voids

- Captures hidden geometries in a single scan

- Supports full-part validation for complex assemblies

Limitations of X-Ray and Computed Tomography (CT):

- Expensive and slower scanning

- Requires radiation safety protocols

- Limited by part size and material density

Best for: Internal inspection and quality verification of critical parts such as casting inspection, additive manufacturing, and defect detection.

Comparing Offline, At-Line, and Inline Automated CMM Metrology Across Technologies

| Setup Type | Description | Compatible Automated CMM Technology | Advantages | Limitations |

| Offline | Dedicated measurement lab away from production |

|

|

|

| At-Line | Near-production, often to the side of production for sampling |

|

|

|

| Inline | Fully integrated into production |

|

|

|

Polyrix Surround.Scan™ bridges offline, at-line, and inline systems, delivering high-speed, automated metrology-grade precision without contact, markers, or any required movement of sensor(s).

Robotics in Industrial Metrology

Integrating robots with metrology enables automated, continuous inspection. Robots can position scanners, cameras, or parts for precise, repeatable measurements.

Advantages of leveraging Robotics:

- Enables real-time quality control

- Reduces handling and cycle times

- Compatible with multiple inspection tools

- Supports closed-loop production feedback

Robotics limitations to consider:

- Robot speed may constrain scan rate

- Requires strict calibration and safety standards

- Repairs can be costly in case of collisions or maintenance

Choosing the Right Metrology Strategy

Consider the following when selecting a metrology solution:

- Accuracy vs. Speed – Balance tolerance requirements with production throughput

- Part Complexity – Evaluate accessibility, hidden features, and geometry

- Production Environment – Lab versus shop-floor conditions

- Automation Goals – Robot, conveyor, and MES integration

- Scalability – Handle multiple part types efficiently

- Value – Price and desired outcomes, including potential cost savings from reduced returns and product recalls

Flexible systems like Polyrix Surround.Scan™ often provide the ideal combination of speed, precision, and automation.

Experience Real-Time Industrial Metrology with Polyrix Surround.Scan™

Polyrix Surround.Scan™ transforms automated inspection with multiple structured light sensors offering full 3D measurement without part rotation or manual setup.

- Automation-ready: Optimized for production environments; single-button operation perfect for at-line, offline, and inline metrology

- 360° coverage: Multi-baseline (combinatorial coverage) provides full part scanning in seconds

- Fast and precise: Production-speed inspection with metrology-grade accuracy

Enhance your quality control with a non-contact, high-speed, and data-rich metrology solution.

➡️ Learn more about Surround.Scan™ or contact our team to discover how it can improve your automated inspection strategy.

Subscribe to Our Blog

Related Posts

From Lab Bottlenecks to 100% Inline Inspection

Transforming Manufacturing with Screenless Augmented Reality