Revolutionizing Adaptive Manufacturing for Collins Aerospace

Challenge

Collins Aerospace needed a metrology solution that could support adaptive machining processes by providing accurate, real-time feedback. The solution had to be fully automated, reliable in varying environments, and capable of high-volume scanning with traceable accuracy.

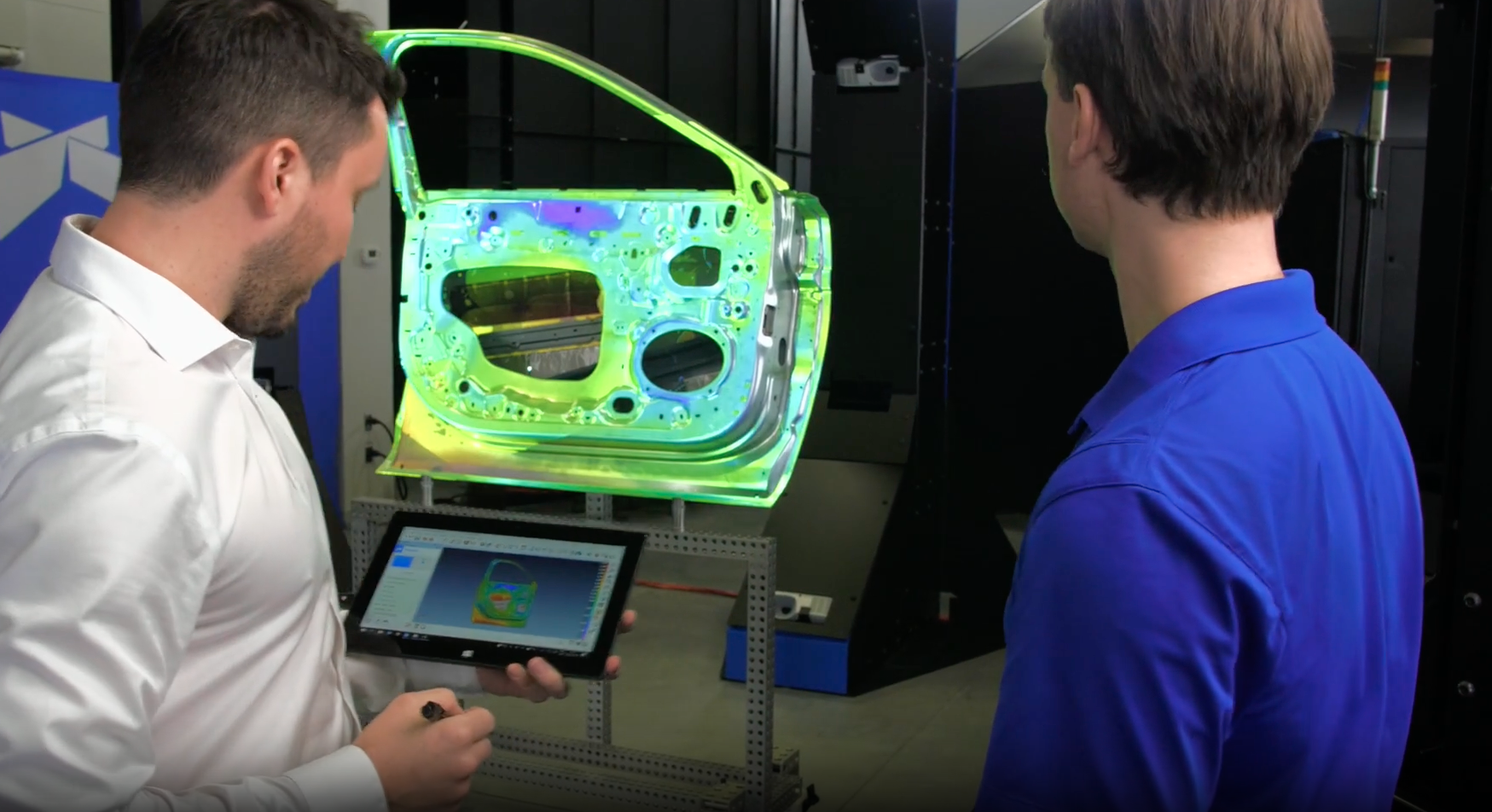

Polyrix Solution

After evaluating multiple 3D scanning technologies, Collins selected the PolyScan XM — featuring a carbon fiber structure for thermal stability. Integrated into a robotic cell, the scanner performed full surround scans in under 30 seconds. Traceable ball bar artifacts enabled continuous health checks to ensure consistent results.

Outcome

- Over 35,000 parts successfully scanned with NIST-traceable precision (±25 microns)

- Fully automated scan-to-machine workflow for adaptive machining

- Improved operator safety and reduced exposure to hazardous materials

“Fast, 3D volumetric scans that are NIST-traceable to ±25 microns have made Polyrix scanning solutions the only choice for our aerospace automation initiatives.

With 35,000 scans of rock-solid precision, Polyrix is driving a paradigm shift in metrology performance, enabling our customers to enhance their products with accuracy and confidence.”

Get a PDF Case Study in your Inbox

Relevant posts

Subscribe to Our Blog

Related Posts

Exploring the Different Types of Automated Coordinate Measuring Machines (CMMs): Tactile Probe, Laser Interferometry, Laser Scanners, Structured Light, and X-Ray for Precision Manufacturing

Transforming Manufacturing with Screenless Augmented Reality