Generative 3D from Images vs. Industrial 3D Scanning

Recent advances in AI generative models have enabled impressive methods for reconstructing 3D objects from images. Today, online tools allow users to upload photographs, or even AI-generated views, and obtain a convincing 3D model within minutes.

Recent advances in AI generative models have enabled impressive methods for reconstructing 3D objects from images. Today, online tools allow users to upload photographs, or even AI-generated views, and obtain a convincing 3D model within minutes.

This naturally raises an important question: Will these AI-driven approaches transform how 3D scanning is performed in manufacturing?

At first glance, the similarity seems obvious. Both generative 3D tools and industrial systems such as PolyScan take images as input and produce a 3D model as output.

However, the fundamental difference lies not in the inputs, but in the purpose and physical meaning of the resulting model.

Image details: Fantasy character AI image generated using OpenAI’s ChatGPT 5.2. Prompted by: Sebastien Quirion

The Core Difference: Visualization vs. Measurement

Image-to-3D generative systems, such as Tencent Hunyuan 3D and similar methods, are designed primarily for visual realism. Their goal is to produce models that look plausible to the human eye for applications like gaming, digital content creation, or e-commerce visualization.

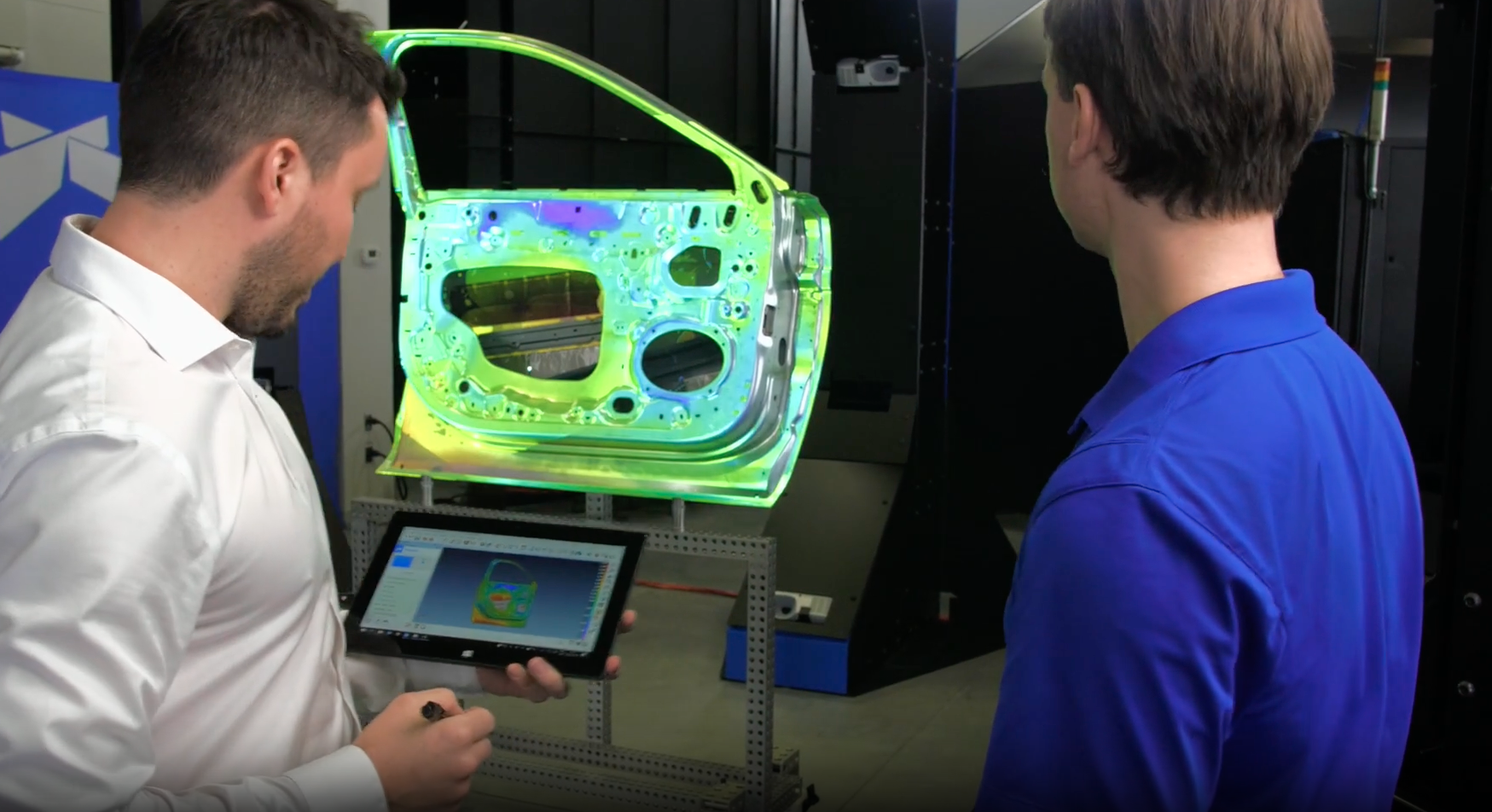

Industrial 3D scanning systems, by contrast, are designed for metrology, the science of measurement. By definition metrology depends on precision, accuracy and standardization.

This distinction is not merely about achieving higher precision. It reflects a deeper conceptual difference:

Generative 3D aims to create plausible geometry.

Metrology 3D must recover physically accurate geometry.

In practice, this means that distances measured between any two points in a metrology-grade model must correspond to real-world distances, often with errors limited to tens of micrometers.

This requirement stems directly from manufacturing tolerances, which routinely fall within fractions of a millimeter. Measurement systems must therefore be significantly more precise than the parts they validate.

|

|

.png?width=266&height=400&name=Various%20reference%20views%20of%20the%20same%20fantasy%20character%20generated%20using%20Google%E2%80%99s%20Nano%20Banana%20Pro%20based%20on%20the%20previous%20image.%20Prompted%20by-%20Sebastien%20Quirion%20(22).png)

|

AI 3D model generated from the previous reference images using Tencent’s Hunyuan 3D model. Prompted by: Sebastien Quirion |

What Does It Mean to “Measure” in 3D?

At its core, image-based 3D measurement relies on a single geometric principle: A 3D point is obtained from a triangulation of this point from multiple viewpoints.

For a point to be measured, it must be identifiable across multiple images so that its 3D location can be computed through precise camera geometry. While this sounds straightforward, it introduces fundamental challenges that generative methods do not need to address.

Why Measuring from Images Is Fundamentally Hard

1. Hallucination vs. Truth

Generative systems are designed to fill missing information. They produce watertight models by inferring plausible shapes where data is incomplete.

This behavior is desirable for visualization, but unacceptable for measurement.

In metrology:

- Missing data cannot be invented.

- Every reconstructed point must be supported by actual observations.

- Measurement uncertainty must be quantified.

In a manufacturing context, a visually perfect model that contains inferred geometry is useless, and potentially dangerous.

2. Textureless Surfaces Cannot Be Triangulated

Triangulation requires identifiable features.

Consider uniform surfaces, extremely common in manufactured parts, which provide no visual cues for matching points between images. Generative models handle this easily: they simply reconstruct a smooth surface that “looks right.”

By contrast, measurement systems cannot do this. To address this, industrial scanners rely on active illumination, such as structured light projection. By projecting controlled patterns onto the surface, artificial features are created that enable precise triangulation even on perfectly smooth materials.

This is a fundamental reason why passive image-based generative approaches cannot replace active metrology systems.

The Role of AI in Measurement

AI still plays an important role in industrial 3D scanning, but in a different capacity.

Its strengths lie in:

- Noise reduction

- Data fusion

- Defect detection

- Automated inspection planning

- Prior-based interpretation of measurements

However, a critical distinction must always be maintained: AI priors can guide interpretation, but they must never replace measured reality.

In metrology, the model must reflect what is observed, not what is statistically likely.

Conclusion

Generative 3D reconstruction and industrial 3D scanning share similar inputs, but they serve fundamentally different objectives. Generative systems aim to produce plausible geometry for visualization. Metrology systems aim to recover physically accurate geometry for measurement. Because of this difference, advances in generative AI will complement industrial scanning workflows, particularly in data processing, but they are unlikely to replace the core physics-based measurement principles that metrology depends on.

Relevant posts

Subscribe to Our Blog

Related Posts

The Automotive Quality Future: Industry 4.0 & Motionless 3D Inspection

Mastering 100% Inline 3D Inspection: Speed, Accuracy & Traceability

.png?width=268&height=400&name=Various%20reference%20views%20of%20the%20same%20fantasy%20character%20generated%20using%20Google%E2%80%99s%20Nano%20Banana%20Pro%20based%20on%20the%20previous%20image.%20Prompted%20by-%20Sebastien%20Quirion%20(12).png)